here present the article is knowledge about the construction of 3 phase transformer.

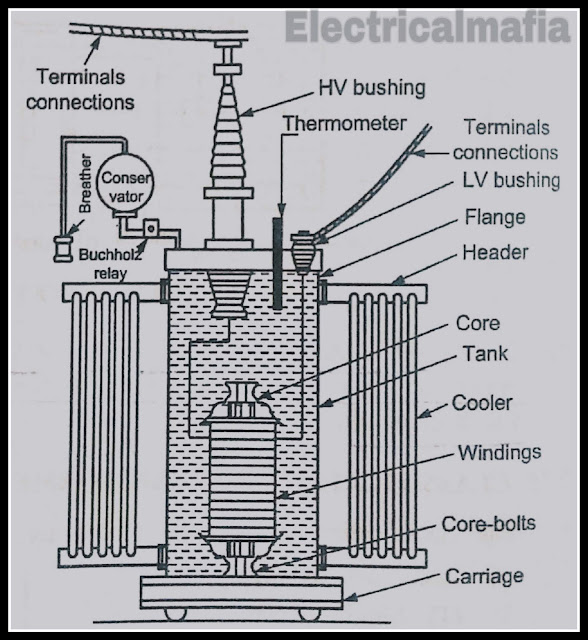

- A three phase transformer has three primary windings and three secondary windings wound on a common magnetic core.

- The core and the windings are enclosed in a tank filled with dielectric oil.

- The terminals of the primary and secondary windings are connected to the interal end of the bushings.

- The bushings provide the necessary insulation to the conductor.

- The bushings are supported on the tank cover.

Accessories of transformers:

the various accessories used in the transformer are :

1. conservator tank

2. high voltage and low voltage bushings

3. breather

4. Buchholz relay

1. conservator tank:

- It is a large size cylindrical tank which is connected by pipe to the transformer.

- The conservator tank is filled with transformer oil up to a certain level.

- The remaining portion of the tank is filled with air.

- Conservator oil is in communication with tank oil.

- Expansion contraction of transformer tank oil is accommodated by the air cushion in the conservator.The direct contact external air with oil is avoided.

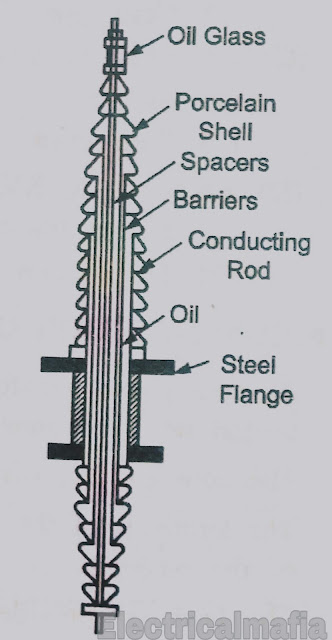

2. high voltage bushings:

- The function of high voltage bushings is to provide insulating support to a conductor passing through earthen tank.

- Bushing comprises of a central conductor surrounded by graded insulation, A bushing is necessary when a conductor is taken out through a metallic tank,at earth potential.

- Porcelain bushing can be used up to 20 kV. Such a bushing consists of a single porcelain bushing,through which a single conductor is taken out.

- Oil filled bushing is used for 33 kV applications.For 132 kV and above,oil impregnated paper condensor bushings are used.

3. breather:

- the breather is filled with silica jel. the function of silica jel is to absorb moisture.

- It is fitted between the air space of conservator and the outside vent.

- The brething of transformers during load takes place through breather.

- When the load increases, the oil expands and the air from conservator is expelled.

- During reduce load cycle,the oil in the conservator falls down and the atmospheric air is breathed in.

- This incoming air is taken through the silica-jel.

- Dry silica jel is of pale pink colour.It turns blue when it absorbs moisture.

- The wet silica jel can be re-used after drying.

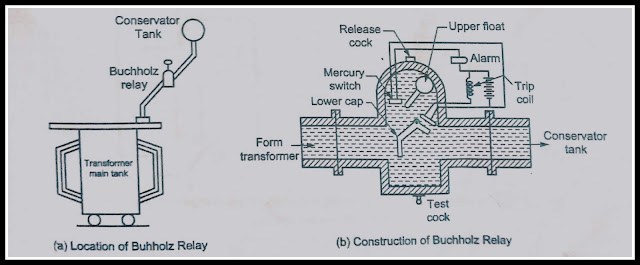

4. Buchholz relay :

- These relays are used for the protection of oil immersed transformers against all kinds of internal faults having rating more than 750 kVA.

- It is a gas operated relay which is installed in the pipe connecting the conservator with the main tank.

- Whenever any minor fault occurs,current leaks and heat is produced. Due to this heat,some oil evaporates in the transformer tank(about 70%hydrogen).

- Since hydrogen gas is light,it tries to go into the conservator tank via relay.During the process, some gas and oil vapours are collected in the top chamber while passing to the conservator and the oil level in the tank falls.

- The mercury type switch attached to the float is tilted, thereby closing the alarm circuit and the bell rings in the control room.

- This gives a warning to the attendant,that some serious fault is going to occur inside the transformer.

- When any severe fault takes place,larger volume of gas is generated in the main tank. These gases rush towards the conservator in a Buchhloz Relay resulting the tilting of mercury switch fitted on hinged type gap.

- The trip coil contacts of the circuit breaker are closed.The pressure in the chamber can be released and the gas is emitted to refill with oil.A test cock is installed at the bottom of the chamber to allow air to be pumped into the chamber for test purpose.

5. Tap Changers:

|

| Tap changer |

- Tap changer is fitted with the transformer for adjusting the secondary voltage.The adjustments in secondary voltage can be made by OFF circuit tap changer.Such adjustments are for seasonal load variations.

- The tap is changed only after opening the circuit breaker on the supply side.Daily or short time voltage adjustment is made by means of ON load tap changer.

- The tapping of ON-load tap changer can be changed without interruption in load current.

- the modern practice is to install the tap changer within the transformer tank..

Exllent work

ReplyDeleteI really appreciate this wonderful post that you have provided for us. I assure this would be beneficial for most of the people. Thanks for sharing the information keep updating, looking forward to more posts. Copper Control Cable In India

ReplyDeleteI have a fondness for your post. I think that you are very smart and knowledgeable. Your articles contain so much insight and information. Best Flexible Cables Suppliers In India.

ReplyDelete

ReplyDeleteThanks for sharing this blog.It's Very Useful for me.

Good to hear you.Thanks for sharing this informative blog.

Trutech Products is leading the Best Transformer Manufacturers in Mumbai at the best cost Visit Us For:

Transformer Manufacturers in India

Transformer Manufacturers in Mumbai

Control Transformers

Thank you so much for this information. If you are looking for Transformers Manufactureres in Pune, Visit Trutech Products, One of the best Transformer Manufacturers in India.

ReplyDelete