Here present the artical of knowledge about the construction of a d.c. machine.

CONSTRUCTION OF A D.C. MACHINE.

The construction of a dc generator is identical to that of a dc motor, both physically and electrically.the same machine may be used as motor or generator.

A dc machine consists of the following essential parts:

- Field magnets or field system - stationary part

- Armature - rotating part

- Commutator and brushes

- Bearing

- Shaft

1. Field magnets:

- The field magnets is the stationary part of the machine.

- It produced the magnetic field in the machine and provides the necessary excitation for the operation of machine.

- The field magnets consists of following parts:

(A) yoke or frame

(B) pole cores and pole shoes

(C) field coils or pole coils

(A) yoke:

The yoke or frame serves two purposes:

1- it is provides mechanical support for the field poles and acts as protecting cover for the entire assembly of the machine.

2- it is provides path for the magnetic flux produced by the field poles.

(B) pole cores and pole shoes:

Pole body or pole core houses the field coils at which the magnetic field is produced.

Each pole core has a pole shoe having a curved surface.

The pole shoes serve two purposes:

1. The provide a support to the field coils place on the core.

2. They also spread the magnetic flux uniformly over the armature periphery i.e . In the air gap.

(C) field coils or pole coils:

Each pole core has one or more filed coils or windings place over it to produce a magnetic field. The MMF developed by the field coils produce a magnetic flux that passes through the pole pieces , air gap, armature and yoke.

All the field coils are connected in series in such a way that so as to produce opposite polaruties at the adjacent poles.

2. Armature:

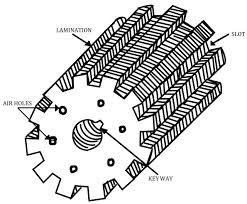

The armature is cylindrical drum consists of armature core and the winding. The armature core is made of thin circular laminated stampings of silicon steel to reduce the hysteresis and eddy current losses. The thickness of the laminated stampings varies from 0.3 mm to 0.5 mm. the armature core is provided with slots on its circumference in which the conductors are housed.

3. Commutator and brushes:

All the field coils are connected in series in such a way that so as to produce opposite polaruties at the adjacent poles.

2. Armature:

The armature is cylindrical drum consists of armature core and the winding. The armature core is made of thin circular laminated stampings of silicon steel to reduce the hysteresis and eddy current losses. The thickness of the laminated stampings varies from 0.3 mm to 0.5 mm. the armature core is provided with slots on its circumference in which the conductors are housed.

the armature is free to rotate betweeen the field poles and it is mounted on the shaft. the main function of the armature is to support the conductors and causes the conductors to rotate between the electric field.

two type of armature windings are used in dc machines:

1. lap winding

2. wave winding.

when large currents are required it is necessary to use lap winding. because it gives more parallel paths. hence lap winding is suitable for comparatively low voltage but high current machines. In wave windings the number of parallel paths through the armature windingis two(a=2). Hence this winding is used for high voltage and comparatively low current machines.

This winding is made of copper

Physical connection to the armature winding is made through a commutator-brush arrangement. The function of a commutator, in a dc generator, is to collect the current generated in armature conductors. Whereas, in case of a dc motor, commutator helps in providing current to the armature conductors. A commutator consists of a set of copper segments which are insulated from each other. The number of segments is equal to the number of armature coils. Each segment is connected to an armature coil and the commutator is keyed to the shaft. Brushes are usually made from carbon or graphite. They rest on commutator segments and slide on the segments when the commutator rotates keeping the physical contact to collect or supply the current.

4. Bearing:

It is a device which gives free and smooth rotation to the armature. The function of the bearing is to support the rotating armature and to reduce the friction.

Ball bearings are commonly used in small and medium size dc machine. In large heavy duty dc machines, roller bearing are used.

5. Shaft:

The shaft is made of mild steel. The shaft is used to transfer mechanical power from or to the machine. The rotating parts such as armature, commutator and cooling fan keyed to the shaft. A commutator is fixed on one side of the shaft and on the other side, a light aluminum fan is fitted for the circulation of cooling air.

0 Comments: